Water cooling and air cooling are the two common cooling methods for blown film machines. The “better” choice depends on film quality targets, production stability, energy cost, and maintenance conditions. This guide compares water-cooled down-blown systems and air-cooled systems across quality, efficiency, cost, and applications.

Cooling Principle: Water Cooling vs Air Cooling

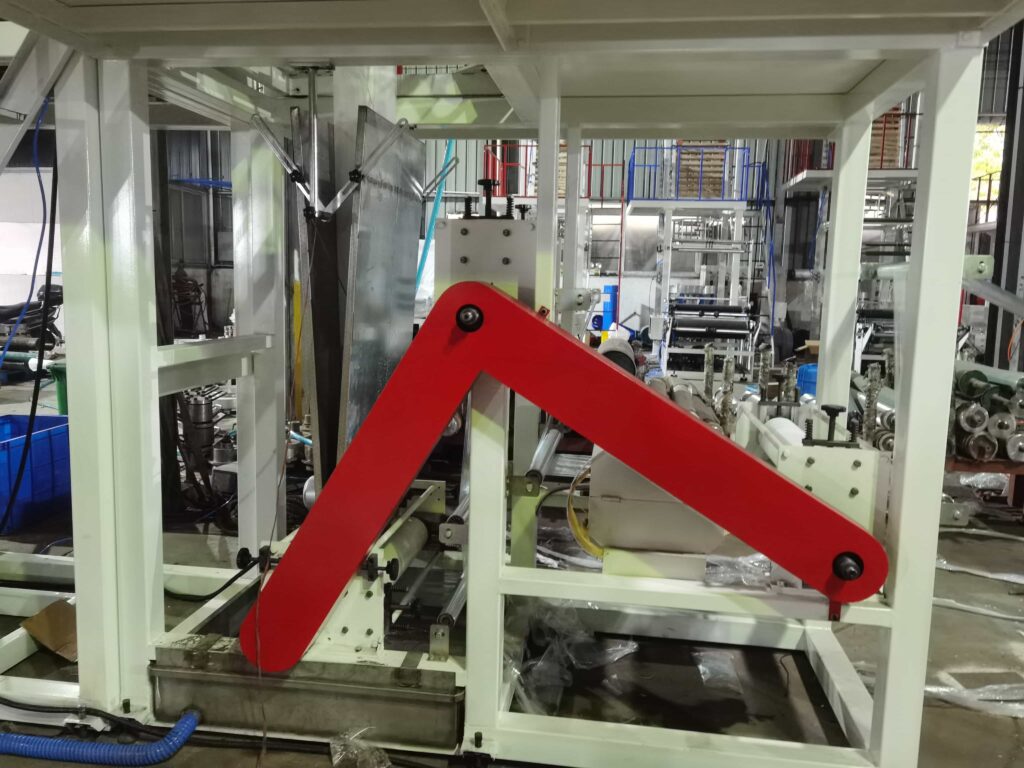

Down-blowing water-cooling blown film machine: Circulating water is used to cool the molten plastic extruded from the die head, so that the film can be quickly shaped.

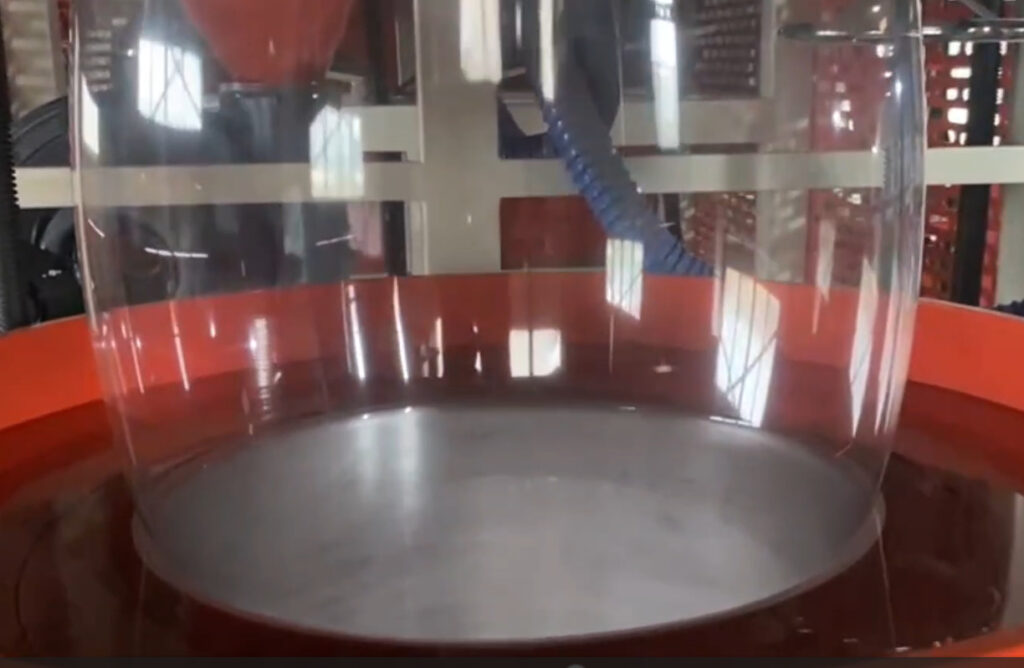

Air-cooling blown film machine: The blower blows cold air to the film bubble to cool and shape the film. The cold air is transported to the surface of the film bubble by the air ring, air duct and other components.

Film Quality Comparison: Clarity, Thickness Uniformity, and Stability

Down-blowing water-cooling blown film machine: It can make the film reach high transparency. And the film has better barrier and heat sealing properties. The surface flatness is high and the wrinkles and distortions are less. Down-blown water-cooled blown film machine is suitable for high-end packaging film.

Air-cooling blown film machine: If the air ring and blower work well together, it can also produce film with uniform thickness and smooth surface. However, in terms of transparency, it is usually slightly inferior to water-cooled film blowing machines.

Production Efficiency: Output Stability and Line Speed

Down-blowing water-cooling blown film machine: The production process is relatively complex. It needs professional technicians to operate. In addition,the existence of water cooling system makes the equipment start and stop relatively slow. The production speed of blown film machine is limited. Down-Blowing water-cooling blown film machine is not suitable for large-scale rapid production.

Air-cooling blown film machine: The structure is relatively simple.It is easy to operate. It starts and stops quickly. Higher production efficiency. The production efficiency is high. Air-cooling blown film machine can meet the production needs of large output.

Equipment Cost and Maintenance Cost

Down-blowing water-cooling blown film machine: Since it is equipped with a water-cooling circulation system, the initial investment cost of the equipment is relatively high. It is also necessary to regularly maintain and replace water cooling equipment and filters and other components. The maintenance cost is also high.

Air-cooling blown film machine:The equipment has a simple structure and does not require a water cooling system. The initial investment cost is low. And the maintenance is economical and simple. The maintenance cost is about half of that of the water-cooled type.

Energy Consumption and Environmental Impact

Down-blowing water-cooling blown film machine: The water-cooling circulation system has high energy consumption. It is not conducive to energy saving and consumption reduction. In addition, the water used in the production process may contain chemical components. There are certain environmental pollution problems.

Air-cooling blown film machine: It uses air cooling, which does not require a lot of water. It saves water resources. There is no water pollution problem. The energy consumption is relatively low. It is more energy-saving and environmentally friendly.

Best Applications: Packaging, Agriculture Film, and Industrial Film

Down-blowing water-cooling blown film machine: It is suitable for occasions with high requirements on film transparency, barrier property and heat sealing property. Such as food, medicine, cosmetics and other high-end packaging. As well as some special applications that require high precision film.

Air-cooling blown film machine: It is widely used in the production of various plastic films.Such as agricultural covering films, industrial packaging films, ordinary plastic bags, etc. Air-cooled film blowing machines can meet the production requirements where film quality is not extremely high.

Quick Decision Guide: Which One Should You Choose?

WILSON MACHINERY is one of the well-known blown film machine manufacturers in China.Our professional technical team has more than 20 years of experience to design and customize the machines to meet every customer’s requirement.

FAQ

Which produces clearer film, water cooling or air cooling blown film machines?

In many setups, air cooling can achieve better optical clarity for certain films, while water cooling often prioritizes fast stabilization and thickness consistency over maximum transparency.

Is a water-cooled blown film machine always faster in output?

Not always. Water cooling may stabilize the bubble quickly in some configurations, but final output depends on screw design, die size, cooling capacity, and line tuning rather than cooling method alone.

Which cooling method is better for thin film production?

Air-cooled lines are commonly chosen for many thin-film applications, but water-cooled systems can be competitive when thickness uniformity and rapid cooling control are the main goals.

Does water cooling increase operating cost because of the circulation system?

It can. Water-cooled systems may add costs for pumps, chillers or cooling towers, water treatment, and maintenance, while air-cooled systems usually have a simpler utility requirement.

Which is easier to maintain: water cooling or air cooling?

Air cooling is often easier because it avoids scaling and water quality issues, while water cooling requires regular inspection of piping, filters, and heat exchange performance.

Which option is more suitable for hot or humid factory environments?

In hot climates, both systems need adequate cooling capacity, but water cooling can offer more consistent thermal control if the plant can manage stable water temperature and treatment.

Can air cooling blown film machines meet high-speed production needs?

Yes. Many modern air-cooled lines run efficiently at high speed when the air ring, blower, and IBC or cooling design are properly matched to the die and resin.

Which cooling method is better for courier bag film and general packaging?

Both are used. The better choice depends on required film properties such as sealing, printability, thickness uniformity, and the buyer’s budget and maintenance preference.

Does cooling method affect film thickness uniformity?

Yes, indirectly. Cooling stability influences bubble behavior, which impacts gauge variation; however, die quality, air ring design, and operator settings are often the biggest factors.

What information should I prepare before choosing a blown film cooling configuration?

Prepare film width, thickness range, resin type, target output, main products, factory temperature conditions, power standards, and your preference for utility complexity and maintenance.