what is AB double layers co-extrusion film blowing machine

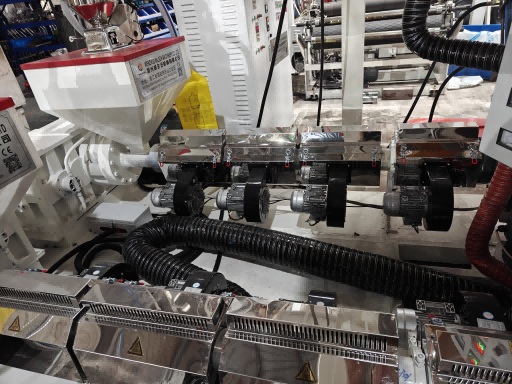

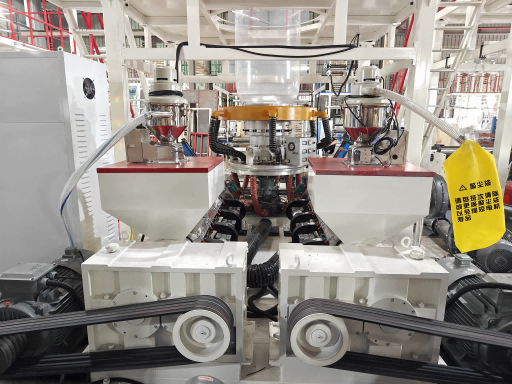

AB double layers co-extrusion film blowing machine has two extruders. This film blowing machine can realize the co-extrusion of two layers of materials. And it can produce films with different colors inside and outside.

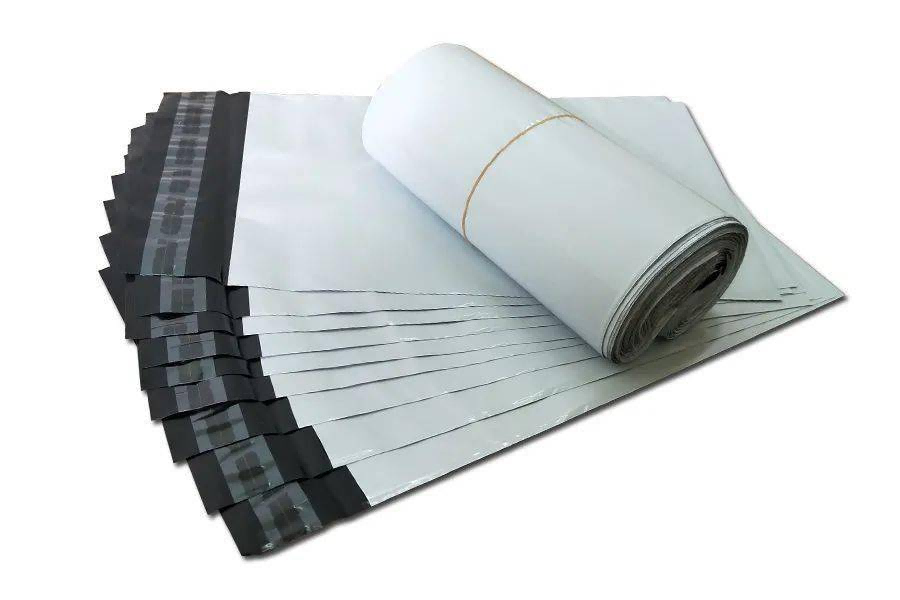

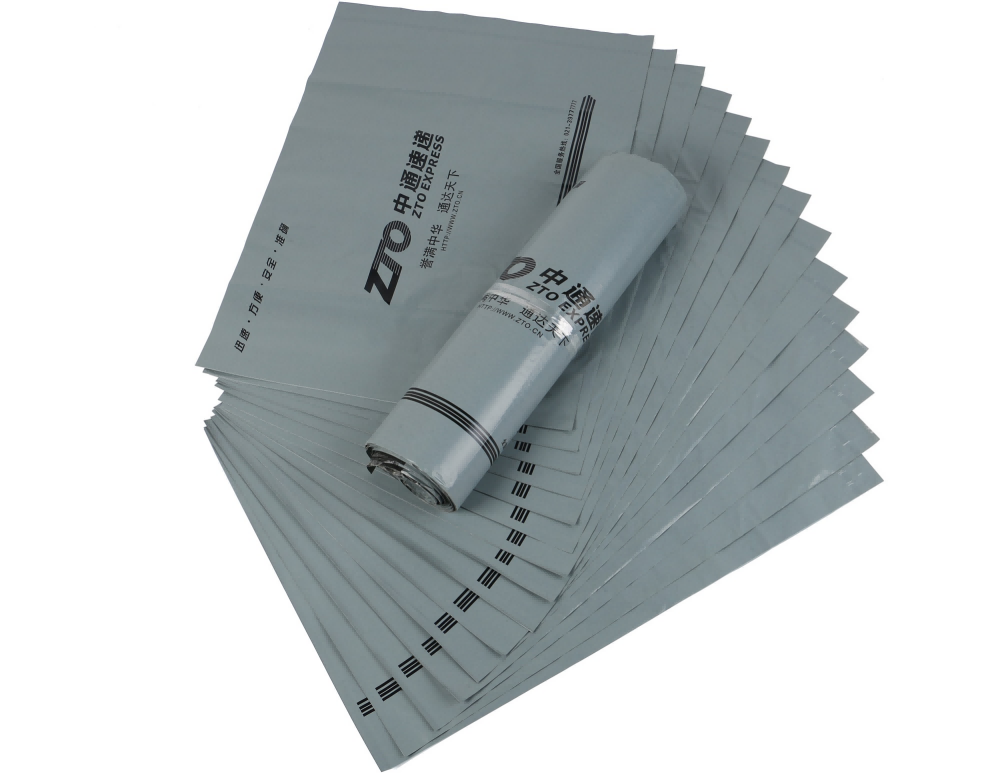

Double layers co-extrusion film blowing machine is suitable for blowing HDPE, LDPE, LLDPE products. Two-layer co-extrusion film blowing machine is specially designed for the production of courier bag film and two-color film!

The courier bag film produced by the double layers co-extrusion film blowing machine has the following characteristics:

- 1. Strong and durable: Ensure that it is not easily damaged during transportation and protect the safety of items.

- 2. Good sealing performance: Effectively prevent the leakage of express items.

- 3. Good printing effect: Can clearly present express information and enhance brand image.

- 4. High production efficiency: Meet the express industry’s demand for large-scale packaging.

Wilson Machinery can provide you with a complete set of professional courier bag production solutions.

FAQ

What is an AB double-layer co-extrusion film blowing machine?

It is a film blowing line using two extruders to form an A/B two-layer structure, allowing different materials or colors to be combined into one film for better performance and cost control.

Which materials are commonly used on AB co-extrusion film blowing lines?

Common combinations include HDPE/HDPE, LDPE/LDPE, LLDPE/LLDPE, or HDPE with LDPE/LLDPE blends, chosen based on stiffness, toughness, sealing needs, and target film thickness.

What products are best suited for AB double-layer blown film?

AB blown film is widely used for courier bags, shopping bags, packaging liners, and two-color films where a tough inner layer and a printable or protective outer layer are needed.

Can AB co-extrusion help improve sealing performance for courier bags?

Yes. Many factories use a softer or higher-MI resin in one layer to improve heat sealing, while keeping the other layer stronger for puncture resistance and handling during transport.

How does AB co-extrusion support two-color film production?

By feeding different color masterbatches to the two extruders, the film can show different colors on each side, which is useful for branding, sorting, or inside-outside appearance control.

Does AB co-extrusion reduce raw material cost compared with single-layer film?

Often yes. A common approach is to keep performance resin in the “functional” layer while using a more economical blend in the other layer, helping reduce overall cost without sacrificing key properties.

What thickness range is practical for AB two-layer blown film?

A practical range is typically around 20–120 microns depending on resin, die size, cooling, and application, with courier bag film often produced in the thinner to mid-range for efficiency.

What are the key quality checks for AB courier bag film?

Typical checks include film thickness uniformity, seal strength, dart impact or puncture resistance, coefficient of friction stability, and print adhesion if the outer layer is intended for branding.

When should a buyer choose AB instead of ABA or ABC structures?

AB is a good choice when you want a clear performance upgrade over single-layer film but prefer lower investment and simpler operation than three-layer systems, especially for standard packaging films.

What information should I provide when requesting a quote for an AB film blowing machine?

Provide target film width, thickness range, resin type (HDPE/LDPE/LLDPE), output requirement (kg/h), product type (courier bag or two-color film), and local power standards so the configuration matches your production goals.