The main components of a blown film machine are the die head, the screw and the air ring.

A:Blown film machine die head

Blown film machine die head, some can be used for many years. Some of them can only be used for one year or even shorter time and have various problems. Why is this? We analyse it through the dimension of die head quality.

- Material aspect

1. Material according to the chemical composition can be divided into alloy steel and carbon steel. They include 42Cromo forging parts, 40Cr forging parts, 42Cromo solid steel, 40Cr solid steel, 45# solid steel, 45# seamless steel. The better ones are 42Cromo forged parts, 40Cr forged parts. The worse one is 45# seamless steel.

2. Material can be divided into hot rolled steel, cold rolled steel, and forged steel and so on according to the forging method

- Screw Processing

1. Car, washing, drilling (roughing, heat treatment, fine turning). In this we have to pay attention to a very important process is heat treatment. Heat treatment is the process of changing the internal structure of steel through the process of heating, holding and cooling. Its function is to improve the properties of the steel and enhance the service life of the die. If the steel is not heat-treated directly to the end of a car, it will increase the amount of deformation.

2. Polished plating. Polished plating includes normal plating and mirror plating. It can also be divided into hard chrome plating and alloy plating ah.

At present, our film blowing machine common configuration is ordinary plating 40cr alloy steel mould head.

B:Screw and barrel

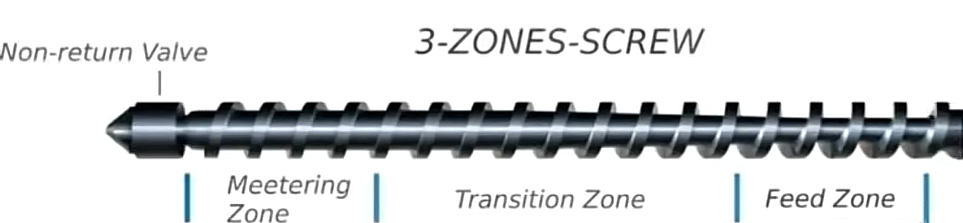

- Screw construction

The screw is generally divided into three sections. There are charging section, compression section and homogenization section (metering section).The feeding section is used to transport the raw material to the front end; Compression section pushes the material forward from deep to shallow. Its main function is to compact the melting material; The last section is the measuring section. The compressed molten material has been quantitatively fixed temperature.

- Screw Material

The screw materials we usually use are 38CrMoALA, 38CrMoALA screw alloy and 38CrMoALA screw barrel double alloy. The alloy material of the screw is more durable.

- Screw L/D ratio

Screw L/D ratio is the ratio of screw length to screw diameter. The screw L/D ratio is the most important factor in the plasticizing effect of a blown film machine. The longer the screw, the longer the material stays in it. The stronger the plasticizing ability. But don’t pursue the length of the screw. We have to customize the screw length according to the characteristics of the material. At present, our factory uses more 30:1 and 32:1.

- Processing of screws

Refined through the process of tempering, shaping, molding, fine grinding, surface nitriding, chrome plating, polishing and so on. Nitriding depth: about 0.7mm, nitriding hardness: HRC55°-58°. It has the advantages of high wear resistance and corrosion resistance.

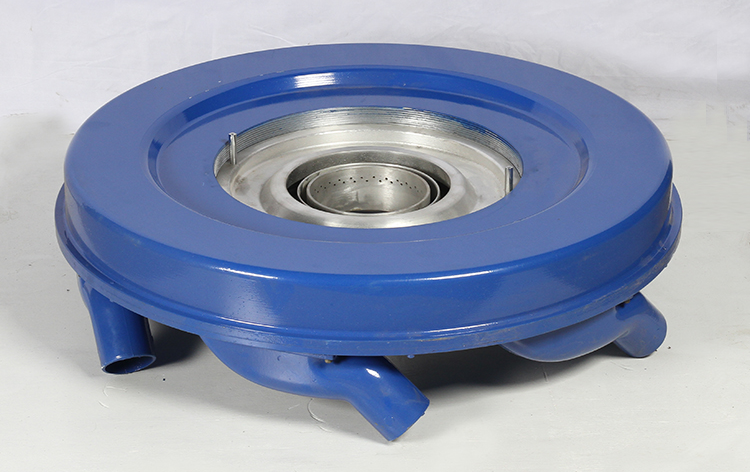

C:Air ring

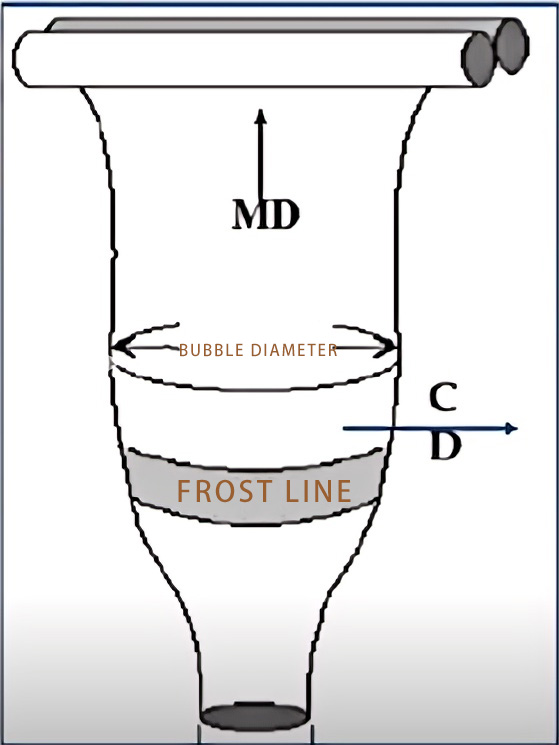

One of the key factors affecting the quality of film is cooling and sizing. Basically, cooling and sizing are the two items of wind ring and blower. Some equipment requires additional chillers, suction fans and so on.

The size of the air volume of the wind ring directly affects the quality of the film. So it is a technical job to grasp its airflow. The inner diameter of the air duct is basically between 1.5 times and 2.5 times of the mold. The width of the air outlet gap is 1~3 millimeters. Most of the air inlets, also known as air nozzles, have 3 to 6. Some machines are bigger with 8, 12 or even more.

There is something to be said for the design of the air ring of a film blowing machine. It has an air duct in it. The wind ring basically has a baffle as a buffer. This can play a role in stabilizing air pressure. So as to ensure that its airflow is uniform. The angle of the wind ring outlet is basically between 45° and 60°. The size of the wind power directly affects the height of the film bubble frost line.

According to the air outlet, there are single air outlet wind ring and double air outlet wind ring. According to the suitable material can be divided into HDPE wind ring and LDPE wind ring. The more high-end wind ring is the fully automatic rotary wind ring. It can automatically measure the thickness of the film.

At present, the single wind ring is more widely used. The price of the film blowing machine with double wind ring configuration is generally high. If you especially pursue the configuration, the pursuit of production capacity, double wind ring blown film machine is more suitable for you.

Blown film machine die head, screw, wind ring, all three have a very big impact on the quality and yield of plastic production. Whether you are just getting into the plastic blown film packaging friends, or has been in the industry for a long time friends, in the choice of blown film machine should pay special attention to these three issues.